GKG | G-STAR | Serigrafía Automática

Solución de impresión de circuitos en Línea

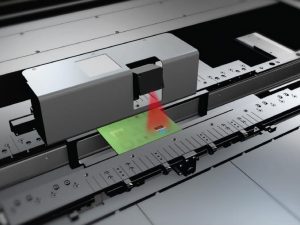

Por encima y más allá de sus expectativas , diseñada para circuitos de hasta 400 mm x 340 mm, G-Star es experto en satisfacer todas sus necesidades comerciales. Logró con éxito la impresión en miniatura 01005. A través del contacto total con la plantilla, nuestro sistema de limpieza mejorado asegura que cualquier pasta restante en pantalla sea eliminada antes de imprimir. La función de inspección de pasta 2D puede detectar una cantidad insuficiente de pasta, puentes y otros defectos. G-Star también está equipado con sistema de fijación de PCB lateral motorizado y superior manual, lo que garantiza una calidad de impresión superior.

| PERFORMANCE | |

| Machine Alignment Capability | 2Cmk @ ±12.5 microns 6 sigma |

| Process Alignment Capability | 2Cpk @ ±25 microns 6 sigma |

| Core Cycle Time (excluding printing & cleaning time) |

< 8.5 secs |

| Product Changeover Time | < 3 mins |

| New Product Set-up Time | < 10 mins |

Categories: Serigrafia, Soluciones SMD

Especificaciones

| PERFORMANCE | |

| Machine Alignment Capability | 2Cmk @ ±12.5 microns 6 sigma |

| Process Alignment Capability | 2Cpk @ ±25 microns 6 sigma |

| Core Cycle Time (excluding printing & cleaning time) | < 8.5 secs |

| Product Changeover Time | < 3 mins |

| New Product Set-up Time | < 10 mins |

| BOARD HANDLING | |

| Max. Size (L x W) | 400 mm x 340 mm |

| Min. Size (L x W) | 50 mm x 50 mm |

| Thickness | 0.4~6 mm |

| PCB Thickness Adjustment | Manual (Auto is option. PCB max. width reduced to 310 mm) |

| PCB Max. Weight | 3 kg |

| PCB Edge Clearance | 3 mm |

| PCB Bottom Clearance | 15 mm (7 mm with optional auto PCB thickness adjustment) |

| PCB Warpage | Max. 1% diagonally |

| Clamping Method | Top clamp (manual) and motorized side clamp |

| Support Method | Magnetic support pins, bars, blocks, Vacuum suction |

| Conveyor Direction | L to R, R to L, R to R, L to L (software control) |

| Conveyor Height | 900 ± 40 mm |

| Conveyor Speed | Max. 1,500 mm/s |

| Conveyor Width Adjustment | Automatic |

| OPERATOR INTERFACE | |

| Hardware | LCD Monitor, Mouse & Keyboard |

| Operating System (OS) | Windows 10 |

| Control Method | Industrial PC controlled |

| I/O Interface | SMEMA Standard |

| OPTIONS | |

| Paste Rolling Diameter Monitoring System | |

| Stencil Apertures Inspection System | |

| Auto Table Adjustment for PCB Thickness | |

| SPI Closed-loop | |

| External Barcode Scanner for PCB Traceability | |

| Handheld Barcode Scanner for stencil, solder paste, squeegee traceability |

| PRINTING PARAMETERS | |

| Stencil Frame Size (L X W) | Adjustable, 470 mm x 370 mm to 737 mm x 737 mm |

| Print Gap (snap-off) | 0~20 mm |

| Printing Table Adjustment Range | X: ±3 mm, Y: ±7 mm : ± 2° |

| Print Speed | 6~200 mm/s |

| Squeegee Pressure | 0.5~10kg (program control) |

| Squeegee Type | Std.: Metal , Option: OPC, rubber |

| Squeegee Angle | Std. 60°, Option 45°, 50°, 55° |

| Cleaning System | Auto wet, dry, vacuum (software select) |

| OPTICAL SYSTEM | |

| Field-of-View (FOV) | 8 mm x 6 mm |

| Fiducial Types | Circle, triangle, square, diamond, cross |

| Fiducial size | 0.5~3.0 mm |

| Vision Methodology | CCD camera look up & down |

| 2D inspection | Max.100 windows to inspect missing & insufficient (std.) |

| FACILITIES REQUIREMENT | |

| Power Supply | AC220V ± 10% 50/60Hz |

| Power Consumption | 2.5kW |

| Air Supply | 4 ~ 6Kgf/cm² |

| Dimension (excluding signal tower) | 1,158 mm (L) x 1,362 mm (W) x 1,463 mm (H) |

| Machine Weight | 1,000kg |