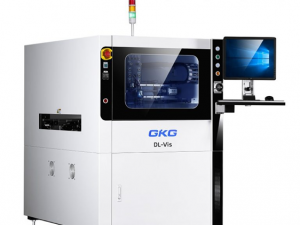

JTU | HCZ-250 | Horno curado (Vertical)

The in-line HCZ Series Vertical Oven minimizes the heat loss, human intervention & provides consistent process control.

It is the perfect solution for:

- Underfill curing

- Encapsulant curing

Opciones

- Customizable sizes

- Barcode scanning software

- MES software (i4.0)

- Double indexing for 2 PCBs in each level

- Preheating conveyor

- Nitrogen inert gas ready

Categorías: Hornos Curado, Soluciones Coating & Dispensing

Especificaciones

| General | ||

| Dimensions | 2,100(L) x 1,750(W) x 2,050(H) mm | |

| Weight | Approx. 1,500 kg | |

| Max. PCB size | 300(L) x 250(W) mm | |

| Object weight | Max. 2 kg per level | |

| Power supply | 3 phase, 380 V AC, 50/60 Hz | |

| Heating system | ||

| Temperature control method | PID closed loop control + SSR drive | |

| Range of temperature set-up | Room temp. – 250°C | |

| Heating configuration | 4 * 2 = 8 heating modules | |

| Heater power | 8 * 6 kW = 48 kW | |

| Temperature control precision | ± 1°C | |

| Temperature deviation | ≤ ± 2°C | |

| Conveyor system | ||

| Conveyor direction | Left to right (Option: Right to left) | |

| Pitch between levels | 25.4 mm | |

| Board or carrier edge clearance | 5 mm | |

| Total level | 60 (30 up, 30 down) | |

| Conveying height | 900 ± 30 mm | |

| Shortest indexing time | 13 sec | |

| Elevator motor | Stepper motor | |

| Conveyor width adjusting method | Motorized | |